By helping you do more with the power you have.

If you're familiar with tech history, you'll recall Blackberry's fixation on making perfect keyboards. Then in 2007, Apple simply changed the game with a software-driven strategy, transforming the customer experience overnight. Apple built an empire on the tight integration of software and hardware, effectively rendering Blackberry irrelevant instead of competing with it. This was the dawn of a new era.

This page from history draws striking parallels to the current battery landscape. Batteries are inherently complex systems that combine mechanical, thermal, and electrochemical phenomena. Since Alessandro Volta's inaugural battery 220 years ago, manufacturers have mainly focused on improving hardware components, pushing their processes beyond Six Sigma, and investing massive capital and resources to increase their yield, scale, safety, and quality. The opportunity tied up in continued hardware development and the associated complexity had left little room for software.

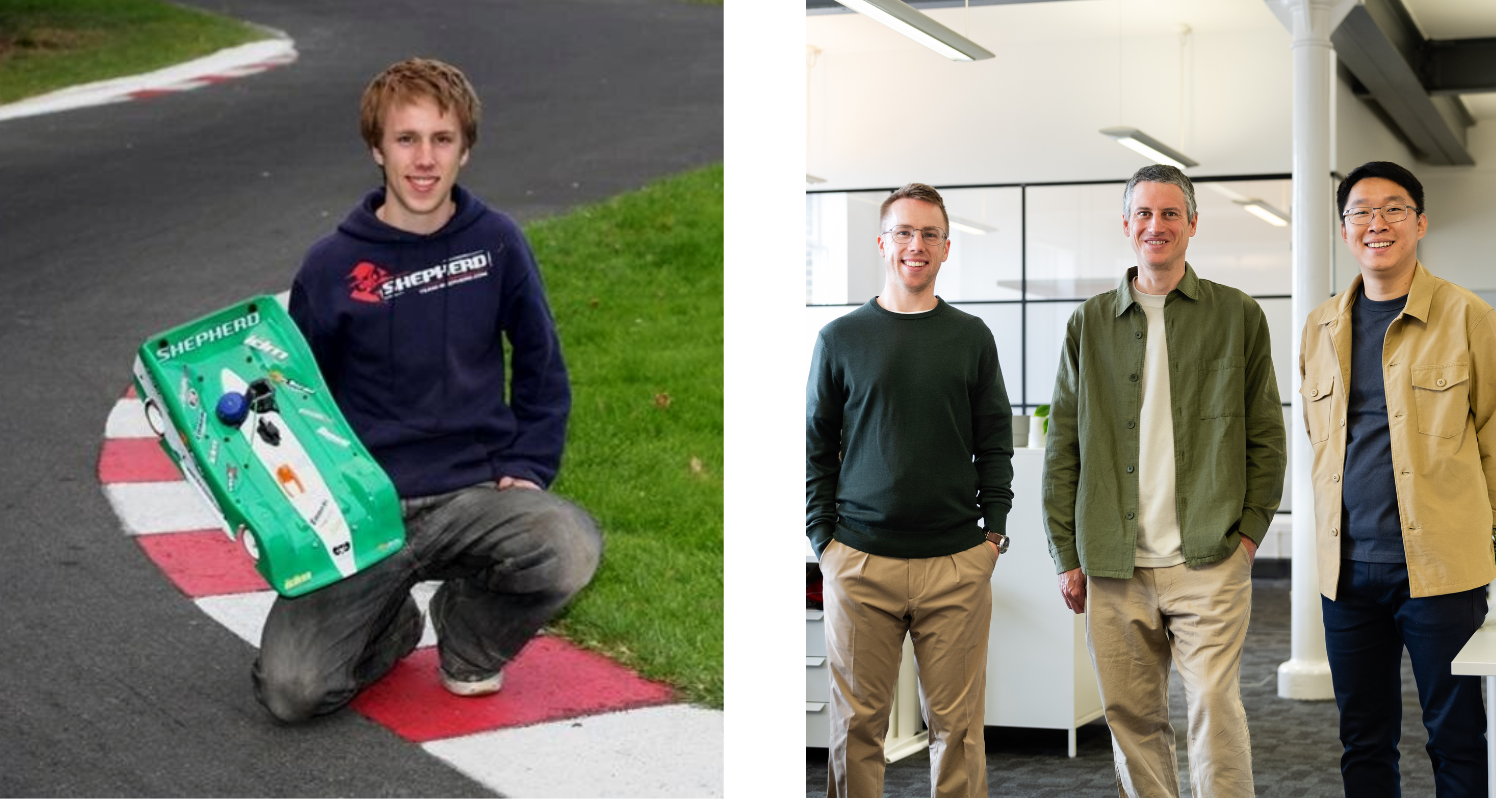

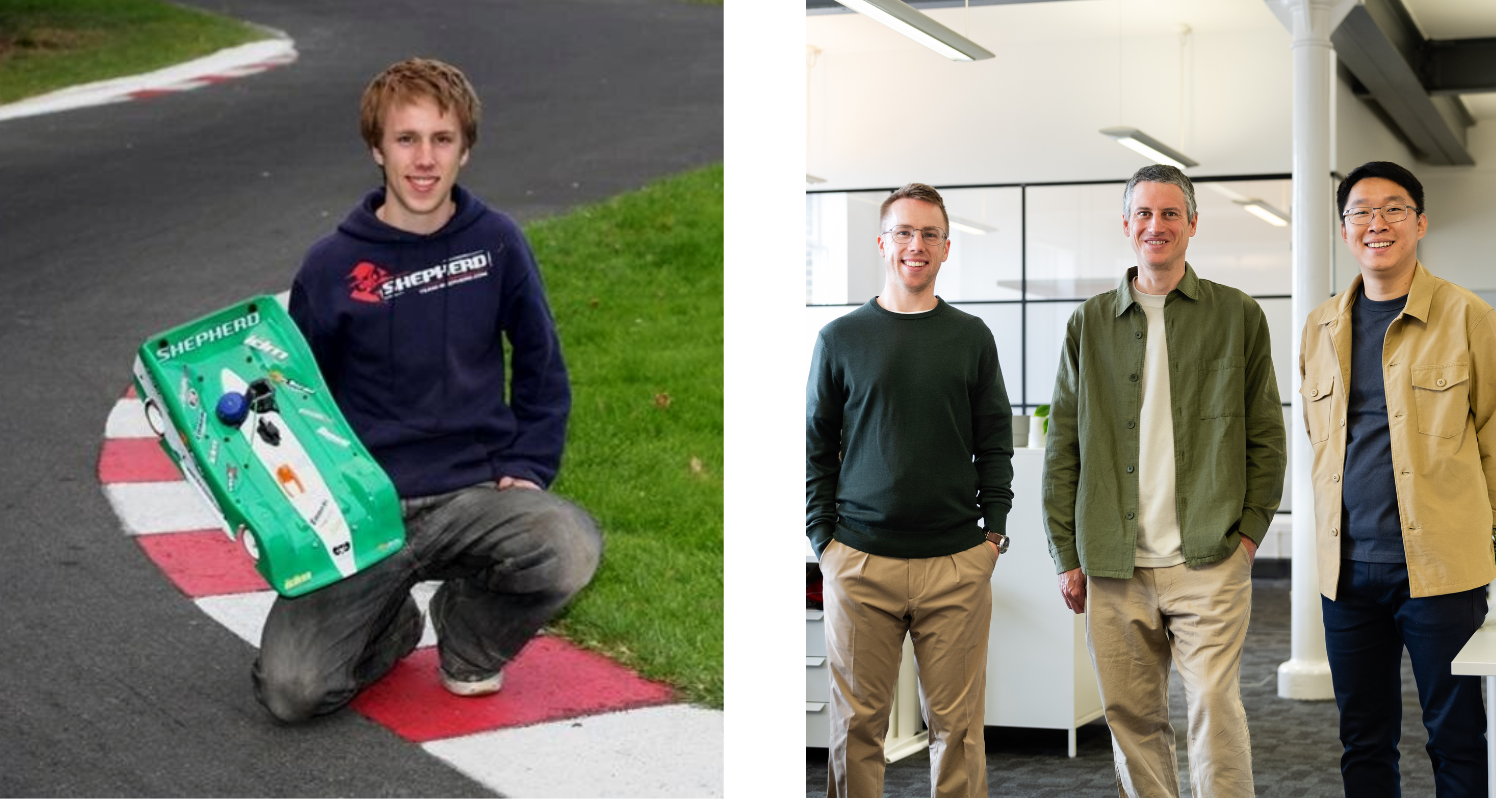

Using the power of software is something dear to my heart, and I know high performance, long-life, affordable batteries are the key to moving us towards a clean power world - and so do my co-founders Yan Zhao and Greg Offer. Our collective dream is for us and our kids to breathe cleaner air, and we can only do that with the electrification of everything.

This is why we created Breathe and brought to the industry a step-change approach: physics-based battery management software. Our technology already brings dramatic improvement to our customers’ products, like

VARTA’s EasyBlade which now reaches 50% state of charge in 43% less time with zero impact on the battery life or

Oppo's Reno8 Smartphone Series which retains 80% of its capacity after 4 years instead of 2.

The Blackberry vs the iPhone (Source: Unsplash)

Thinking from first principles.

Progress is engineered, and so is Breathe. To reach our vision, we carefully evaluated several potential paths, each with different risk/reward profiles.

Our goal was always to maximise the rate of progress, do it fast, and empower global businesses with a massively scalable, affordable, and hugely potent solution.

Through an adaptive software approach and powerful algorithms, we knew we could get much more power from existing batteries at any point in their life and quickly have an impact at scale – because the planet needs us, and we don’t have the luxury of time.

Achieving macroeconomic efficiency is critically important and it's why we designed Breathe to become the technology partner of choice for consumer electronics and electric vehicle companies, with a strong focus on enhancing the end-user experience. Because your laptop should not let you down at the end of the meeting, and you want to safely drive your family home in your electric car before the storm.

What sets our team apart is not just our deep technical expertise, but also our integration within our customers' product design and battery teams.

Our technology and products already resonate with iconic brands, including Varta, Rimac, Cosworth, and Oppo to name a few. (Today, 25+ different models of Oppo’s premium phones have a Battery Health Engine powered by Breathe).

Just like they don’t develop their own operating systems, these major industry players don’t want to reinvent the wheel with in-house development. They believe in standardisation and true partnership to achieve software excellence at scale.

Having a shared vision is also critical when it comes to investors and since Lowercarbon Capital "backs kickass companies that make real money slashing CO2 emissions, sucking carbon out of the sky, and buying us time to unf**k the planet”, we knew they were perfect for us.

“This is why today we’re delighted to announce that Lowercarbon Capital is leading our $10M Series A round, with participation from our seed stage investor, Speedinvest.

We chose to partner with Chris Sacca, Clea Kolster, Clay Dumas and the rest of the Lowercarbon Capital team because we love their conviction for doing what it takes to make this world better, no matter the technology depth or the height of the mountain. We believe it gives our customers, and the planet, the best possible chance.”

Dr Ian Campbell, CEO and Co-founder @ Breathe

L: Breathe CEO and Co-founder, Dr Ian Campbell.

R: Ian with his Co-founders, Professor Greg Offer and Dr Yan Zhao.

Lighting up the path to disruption.

Growing up in Ireland, I was passionate about motorsports. At 12, my father bought me my first competition-grade radio control car. I caught the tail-end of nickel cadmium in the electronics powering my receiver and transmitter electronics and its fascinating memory effect. I experienced the transition to nickel metal hydride and spent years assembling battery packs out of the wonderfully colourful shrink-wrapped cells in the early 2000s. GP and Sanyo were my favourites. Chargers had a knob that you turned up until the current gauge showed the amps were in the red, and charging was a straight constant current until you collided with the voltage ceiling, or the battery got hot.

Then I discovered lithium-ion. I was obsessed with lightweight parts, and this thing was light. And it needed this crazy little device called a voltage regulator because suddenly there were 7.4 V instead of 6 V. I fell hook, line, and sinker in love.

Years later, when I saw what Tesla was doing and I felt that if I – someone who had grown-up playing with engines, the petrol-head child in the Top Gear generation – could see so clearly that electric cars would be the future, there was no way the electrification of the entire auto industry wouldn’t happen.

I wanted to be part of that moment, so I enrolled in a PhD in lithium-ion battery engineering at Imperial College.

This is where I met my co-founder Yan, who had moved all the way to the UK from Lanzhou, China for his secondary education, on a mission to work in Formula 1. A year working on developing diesel engines shocked him into the realisation that combustion engineering was not the future. So, upon returning to university after the summer of 2013, he immediately began developing the battery system for ZEPHiR, Imperial Racing Green’s electric racing motorbike. By 2015, when we met in our PhD programmes under the tuition of Greg Offer, we hit it off immediately.

By 2019, we had won the Energy & Environment track of Imperial College’s Venture Catalyst Challenge. This is when we both declined attractive job offers and instead went to Manchester for a Climate-KIC workshop with a draft business model canvas in the boot and never looked back.

Breathe was born.

Our frustration acted as a driver for us: we did not want science for the sake of science. We wanted to have a real business impact and to make consumers like us infinitely happier.

This is the reason that Greg Offer gets out of bed every day and the reason he has blazed an incredible career at the bleeding edge of battery research. Through his role as Professor at Imperial College London and as the Principle Investigator of the Faraday Institution’s Multi-scale Modelling programme, Greg has maintained a 360-degree view of the industry. He knew the unsolved pain points and was at the cutting edge of thermal management, chemistry (Greg is a chemist by training, and specialises in “converting” engineers, part of his Midas touch), control, and battery design. He joined us as a co-founder, and we went heads down.

We spent the dark winter of 2020 in a basement laboratory, while COVID was bringing isolation and desolation. We scribbled maths on blackboards and wired up commercial off-the-shelf batteries to cyclers running alpha versions of our new physics-based software. It was pure engineering, and the world around us was shut down. Somehow, through these rough times, the silence helped us and we achieved our breakthrough.

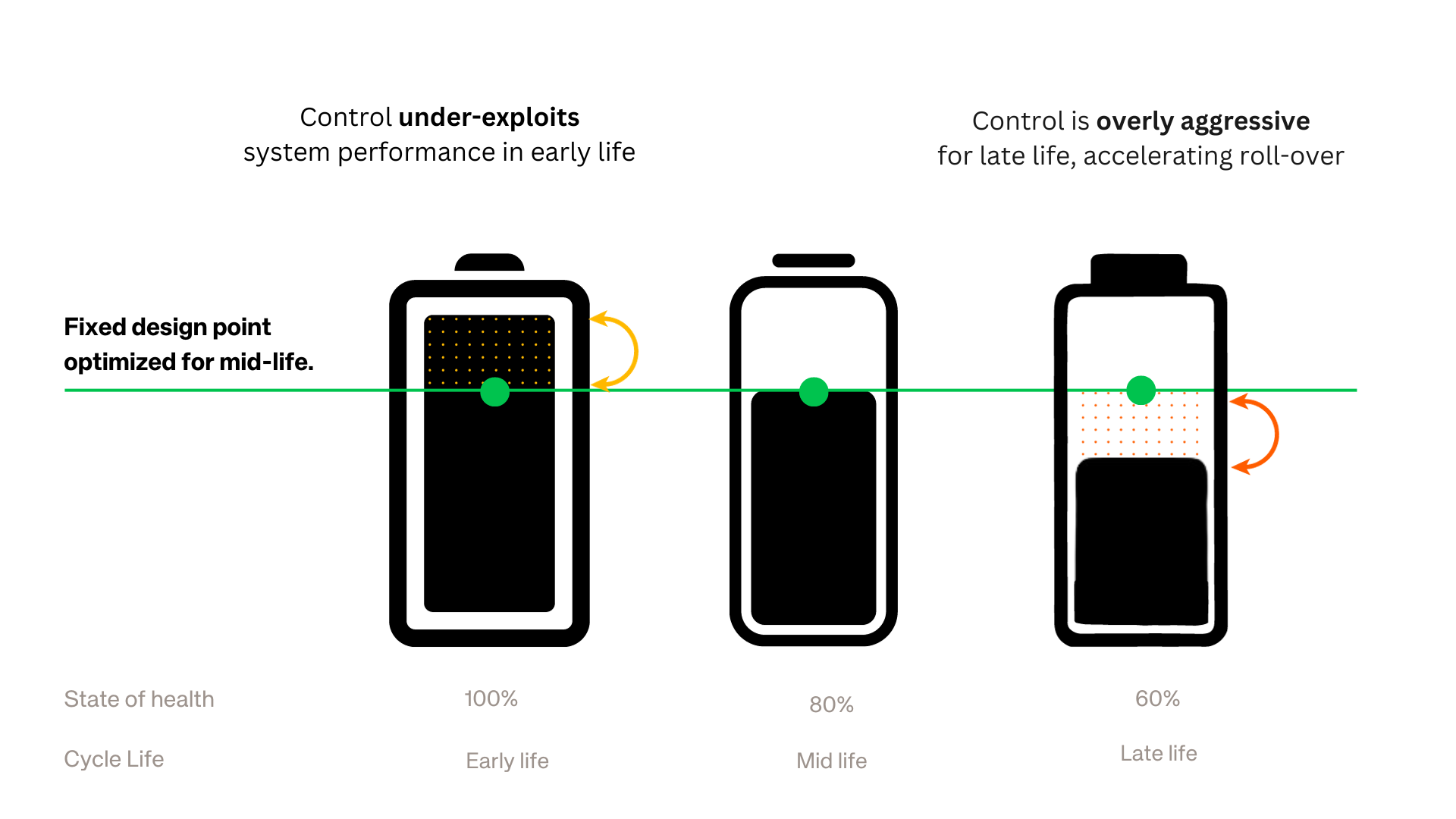

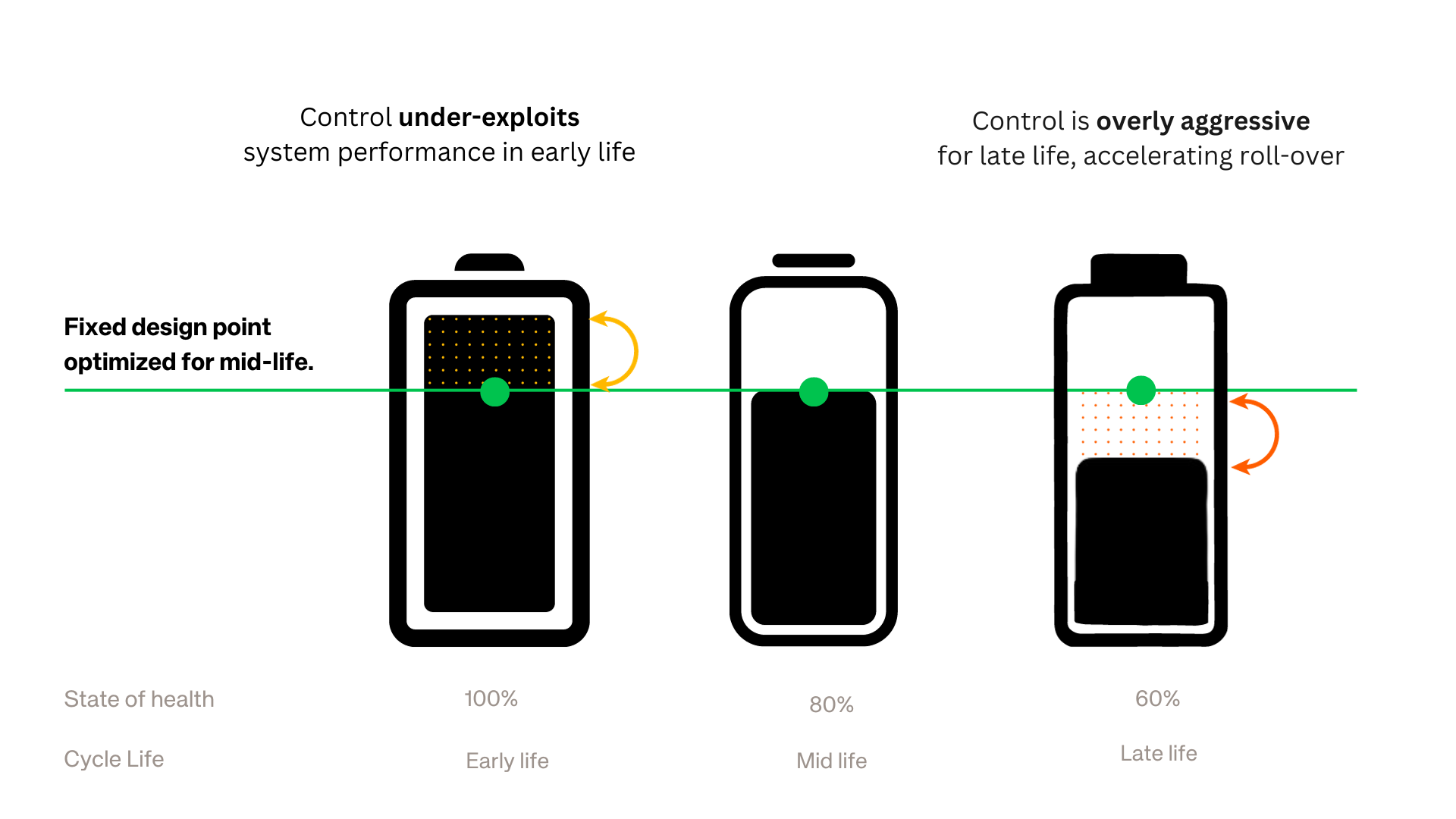

Traditional battery control focuses solely on the 'design point' in the battery's life, resulting in untapped potential and premature decline.

(Source: Breathe Battery Technologies)

Addressing suboptimal battery control.

There’s a beautiful world inside the batteries that power your phone or your electric car.

Atoms move, driven by gradients in the concentrations of electrochemically active species such as lithium. Materials morph from one composition to another, expanding and contracting as they’re intercalated. Copper and aluminium foil shuttle electrons out to semiconductors and motors to satisfy our demands for productivity, music, and acceleration. It’s completely hidden from sight.

Despite this complexity, almost every battery is controlled by only three measurable surface quantities: terminal voltage, temperature, and electrical current. Why? Because they are easy to measure and can be managed according to simple rules, most often implemented as lookup tables.

It’s a one-size-fits-all, “fire and forget” attitude. It’s an approach that assumes that these measurable quantities are sufficiently good proxies of what’s happening inside and that what’s actually happening inside can be safely ignored.

At Breathe we strongly disagree.

We believe relying only on measurable quantities for control is the wrong approach for several reasons:

- It chokes the operating envelope of the battery system, limiting performance, and heavily underutilises the cell materials you’ve paid for.

- It requires engineers to constantly trade between the attributes that end-users care about; charge speed, cycle life, energy density, cost, and safety in a zero-sum environment.

- It ignores the ageing of the battery system.

It’s an approach that leads to “defensive design” – the practice of deliberately over-engineering the battery system and/or limiting its performance to pre-emptively face off against its uncontrolled evolution with ageing. And it relies on significant safety margins to compensate for the lack of adaptability. In the end, this means end users pay more for less.

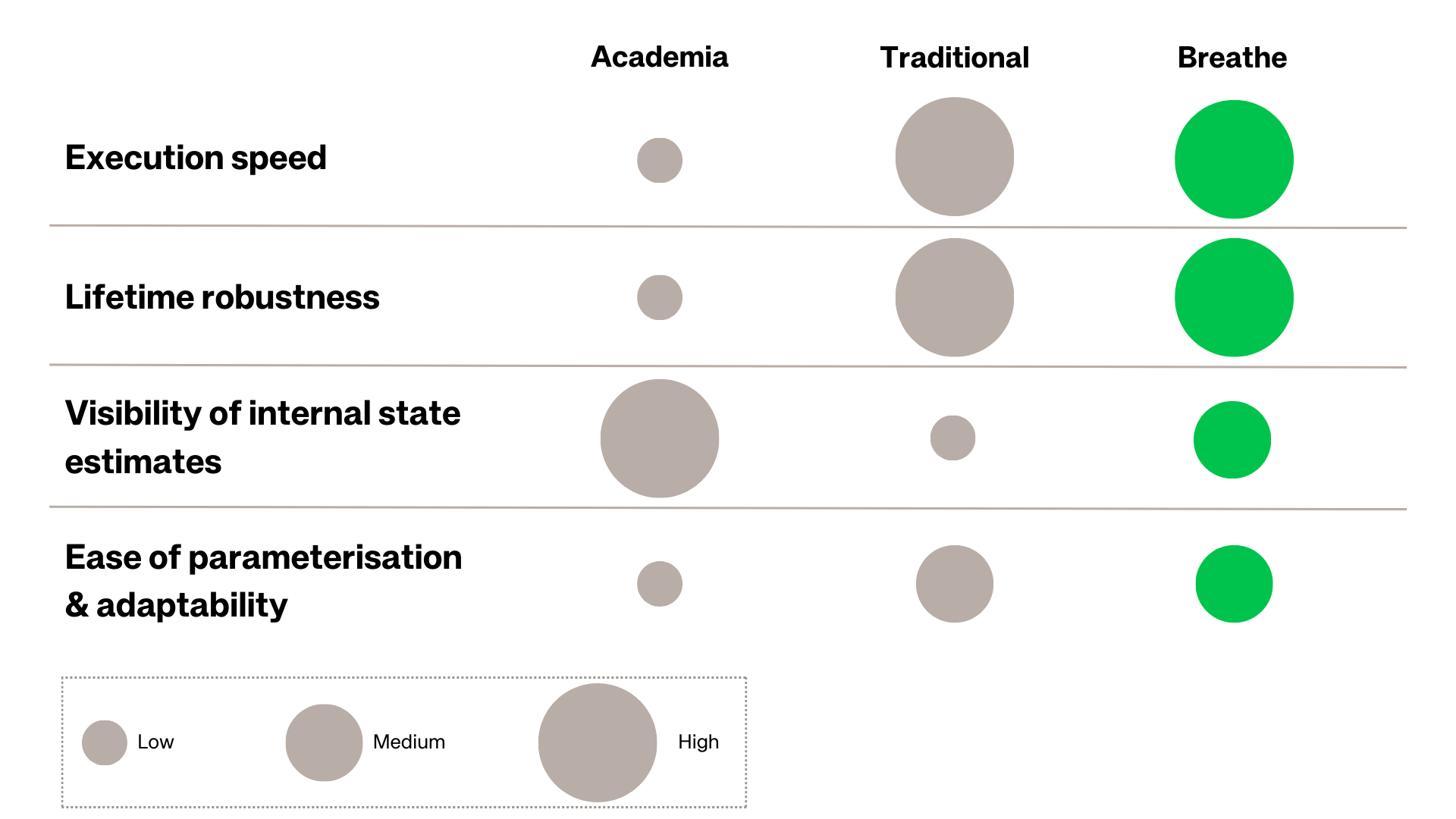

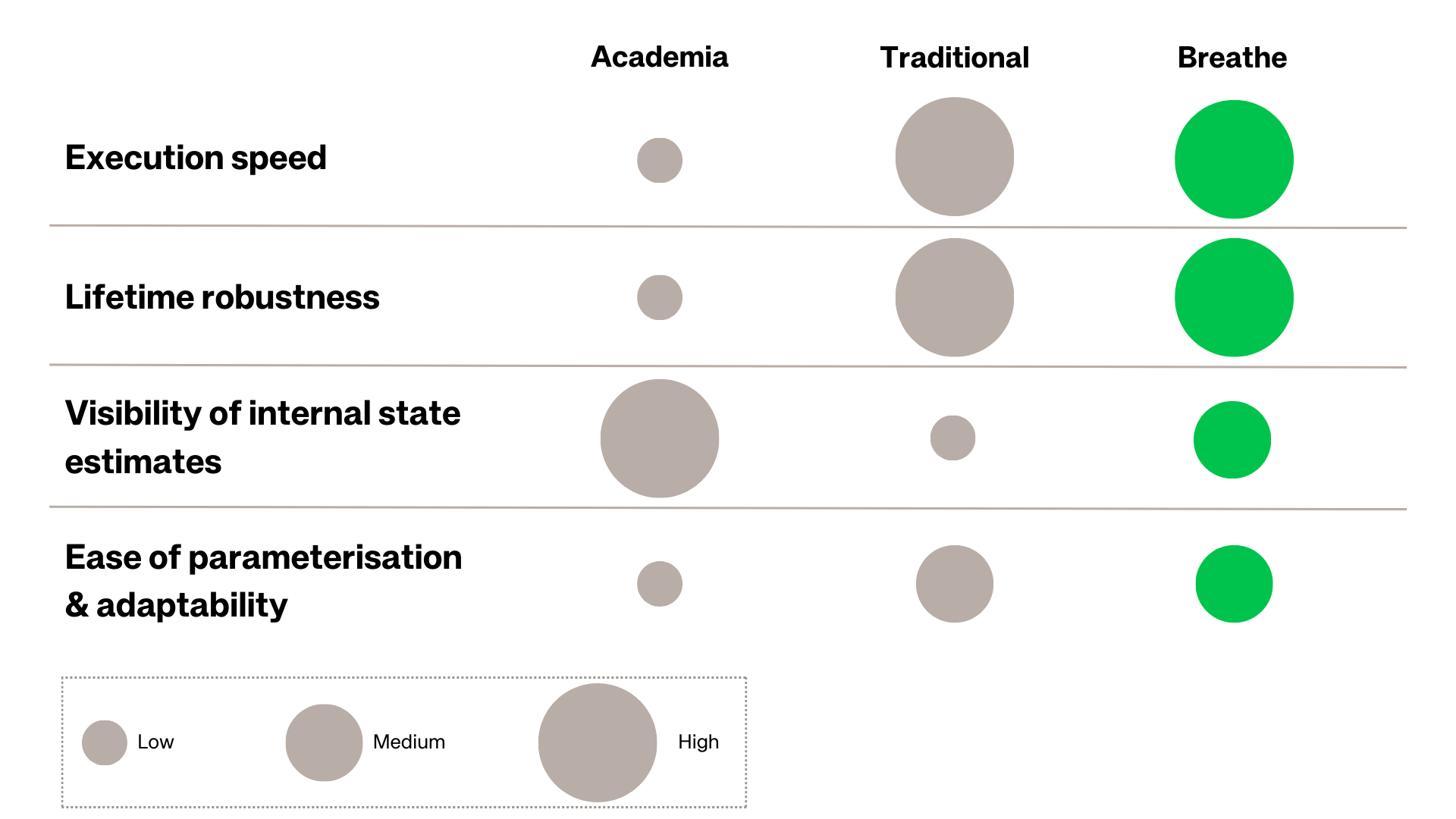

Comparison of battery attributes between Breathe PHI X2. traditional solutions and academia. Circle size represents relative value where large = high and small = low.

(Source: Breathe Battery Technologies)

Making batteries better. Much better.

In August the European Union birthed the new Batteries Regulation which introduces a minimum durability and performance level for batteries. Consumers, regulators and the planet are demanding longer-lasting, higher-performing and more affordable batteries.

So how do we make batteries dramatically better? By leveraging the most advanced algorithms to implement adaptive control and packaging it in a way that’s incredibly simple for our customers to adopt and use.

Since internal states are not directly measurable with sensors at production levels of scale (sensors aren’t yet where they need to be, even in the lab environment; see our research into making them better here), they must be inferred using mathematical models of electrochemistry, running in real-time. Current, voltage and temperature measurements are still necessary, but those parameters are no longer the end goal. Instead, the desired outcome is high-fidelity control of the internal battery states which are being estimated in real-time with a mathematical battery model implemented as software.

We call our model PHI X2. PHI X2 is a platform technology, it’s the base for our initial products:

Breathe Charge and Breathe Life, and it’s our unfair advantage.

With PHI X2, we focus on five key battery model attributes:

- Easy calibration: enables rapid adaption to customers' newest battery chemistry nodes, helping us facilitate tight product launch targets and long-duration maintenance contracts.

- Compatible with computationally low-power microcontrollers: enables backward compatibility with existing devices or vehicles already on the market, and for upcoming product launches, straightforward integration with no hardware changes.

- Low development time: the end goal is the simplest model that makes batteries and consumers happier. Over-engineering models beyond what’s absolutely necessary delays their impact and compounds the problem of lagging battery progress. Our industry is guilty of this, and traditionally there’s been a gulf between battery modelling and product.

- Lifetime robustness: solve the single design point problem to exploit all of the potential in the battery materials at every point in their life, while simultaneously treating the battery gently as it ages. Health adaptive control is just smart.

- Minimum number of internal state estimates: infer only what matters and nothing more – our “size zero” model concept – to focus on resilience, avoid overfitting, and spend our energy on providing product managers with special system-level performance.

We’ve combined these 5 attributes in the most balanced, scalable, and resource-efficient way possible, disrupting traditional academic and industry approaches.

From our PHI X2 platform, we built 2 flagship products:

Breathe Life, which offers charge current control that dynamically manages the electrochemical states inside the battery to enhance cycle life and average state of health. It helps retain pristine system performance for longer and enhances longevity. This is what enables the Oppo Reno8 Series to retain 80% of its capacity after 4 years instead of 2.

And Breathe Charge, which also controls the charging current at every instant. By dynamically managing internal electrochemical states, it increases charging speed while simultaneously adapting to the evolving battery health to enhance safety. It helps VARTA’s EasyBlade reach 50% state of charge in 43% less time with zero impact on the battery life.

L: A live demo of Breathe Charge (shown here against an identical system without Breathe Charge).

R: Textbooks written by a member of the Breathe Scientific Advisory Board, Professor Gregory Plett.

Doing more with the power we have.

Through our technology development, we got to meet the most inspirational and impactful scientists in the field – those who literally wrote the books on battery modelling: Dr Matthieu Dubarry and Professor Gregory Plett. Back when I was falling in love with colourful NiMh packs I was ignorant to dQ/dV and those wonderful green and blue hardbacks, but today, I couldn’t be prouder that Dr Dubarry and Dr Plett are active members of our

Scientific Advisory Board at Breathe.

With our technology and our research pipeline at Breathe, we are now pioneering the next wave of battery performance and control.

We feel it most when our customers arrive in our battery lab, the largest facility of its kind in London, producing over 4,800 hours of validation data daily, and see their battery charge time fall, or their cycle life increase. The performance gains empower them to design more competitive products. Data says something incomparably convincing.

We’ve designed the lab to precisely replicate real-world scenarios of our customer battery systems and align with their rigorous product qualification standards.

For our automotive customers, we replicate compression and forced liquid cooling conditions up to the battery module level. For our consumer electronics customers, we track thickness and temperature rise across cells and packs. In each case we’re working in partnership with our customer to qualify and demonstrate adherence across swelling thresholds, thermal budgets, balancing, and the array of metrics required to advance what it means to be class-leading in laptops, smartphones, headphones, and electric cars.

We love to run demos on live systems so our customers can see the potential and how this can dramatically improve their end-user experience. This is the aha moment. This is what fuels us. Often, we support our customers to get a better handle on their existing battery system performance, too, providing benchmarks and analysis to demonstrate not only the upside of Breathe Charge and Breathe Life, but also to more concretely describe the end-user experience with the customer’s existing control strategies.

Scaling toward our vision.

We resolutely believe this is the time for full-on ambition, the moment in history to spend energy executing on bold and transformational ideas to make batteries better. We’re pumped to be here today, with the prep work behind us, ready for prime time.

If you’d like to share your battery system goals with us, you can do so here. If you’re looking to join a powerful team, you can do that here.

Ad Astra.

Dr Ian Campbell, Co-founder and CEO - Breathe.